Recent Images

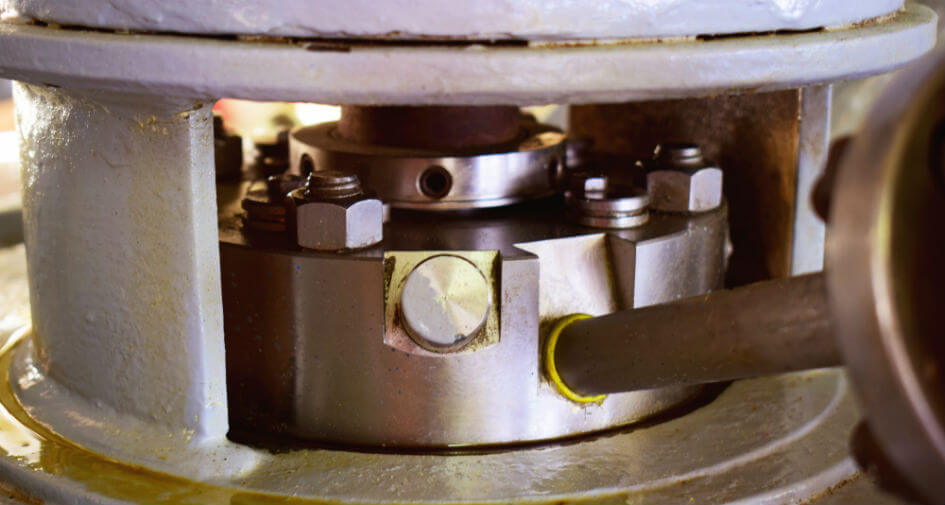

Gland Plate For Mechanical Seal

In crush seal applications the o ring is completely confined and pressure deformed crushed within a triangular gland made by machining a 450 angle on the male cover. When considering gland packing vs mechanical seal solutions mechanical seals are the best for minimizing sleeve damage.

Mechanical Seal An Overview Sciencedirect Topics

Pumps Ii Chemical Engineering Projects

What Is A Mechanical Seal Aesseal

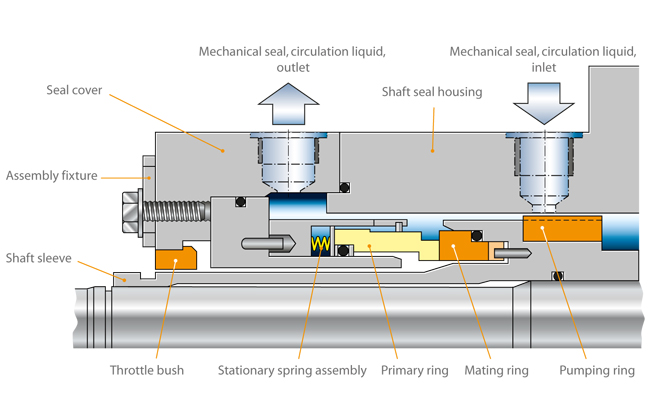

The design of the cartridge seal works to eliminate common causes of seal failure from installation errors and because the seal is presented on its own shaft sleeve any damage that might be caused by a conventional seal to the pump unit is eliminated.

Gland plate for mechanical seal. Squeezed at an angle to the o rings axis crush seals are used in such simple applications as the one depicted in illustration 44. Cartridge seals are self contained units consisting of a shaft sleeve seal and gland plate. The friction of the shaft rotating wears away at the packing over time which leads to increased leakage until the packing is adjusted or re packed.

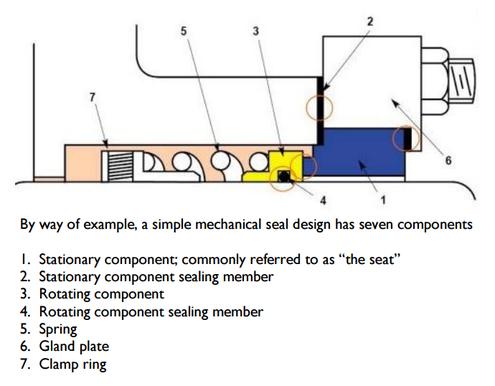

3 of the 4 main sealing points need little explanation but consideration is required for the sealing point between the rotating and stationary components faces. Gland packing is still commonly used in many applications however increasingly users are adopting mechanical seals for the following reasons. The unit is fitted onto the pump shaft as a built assembly and no further fitting is required.

The major comparison between the mechanical seal and gland packing are listed below. This complete assembly can be easily slid onto the shaft and bolted in place thus reducing the potential for installation errors. Today emissions norms in all countries are more stringent and move toward the target of zero emission.

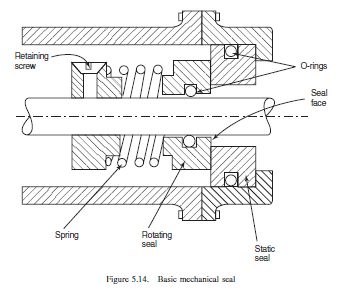

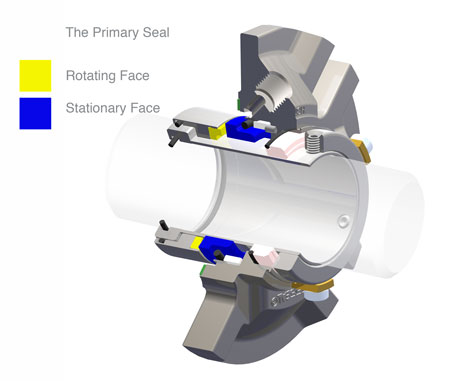

This primary seal is the basis of a mechanical seal design and is what makes it work. Static crush seal gland dimensions. Because of the emission norms the mechanical seals are used to meet the requirement and start replacing gland packing.

Packing seals are removed and replaced much more often than mechanical seals which causes considerable wear and tear to the pumps as they are disassembled and reassembled. The basic components of an end face mechanical seal may be installed directly onto the shaft but a popular approach is to pre assemble the components into some sort of package for ease of installation. When the components are pre assembled onto a sleeve and gland plate the complete assembly is called a cartridge seal.

The seal between the gland plate and stuffing box this is usually a gasket or o ring. The seal between the gland plate and stuffing box this is usually a gasket or o ring. Cartridge seals are an attempt to over come the fitting problems of conventional seals.

This primary seal is the basis of a mechanical seal design and is. 3 of the 4 main sealing points need little explanation but consideration is required for the sealing point between the rotating and stationary components faces. The seal between the gland plate and stuffing box this is usually a gasket or o ring.

Cartridge seals are self contained units consisting of a shaft sleeve seal and gland plate. Sealing points 3 of the 4 main sealing points need little explanation but consideration is required for the sealing point between the rotating and stationary components faces.

How To Set Up A Piping Plan 62 Steam Quench Flex A Seal

The Good Better And Best Of Screw Conveyor Shaft Seals

Mechanical Sealing Options For Long Pump Life Empowering

Raje Dia Pumps Pvt Ltd

Shaft Seal Ksb

Gland Plate Manufacturer From Mumbai

What Is A Mechanical Seal Aesseal

Mechanical Seals For Slurry Pumps Hub 4

Gland Seal Vs Mechanical Seal Difference Between The Two